Products

Stacker

A stacker is a versatile lifting machine designed to lift, move, and stack pallets and goods in places where forklifts might be too large or costly to use. With strong lifting power and a compact design, stackers are perfect for tight spaces, narrow aisles, and small warehouses.

Whether manual, semi-electric, or fully electric, stackers help reduce manual handling and increase efficiency when lifting heavy loads to higher storage levels. They’re ideal for operations that need vertical storage but don’t require a full-sized forklift.

At Hyperack, we supply high-quality stackers that are safe, reliable, and easy to operate—perfect for improving your warehouse productivity while saving space and cost.

Ideal for

- Stacking pallets on racks in warehouses or storerooms

- Moving and lifting goods in manufacturing or logistics operations

- Handling materials in retail backrooms or small distribution centers

- Saving space where forklifts are too bulky to operate

- Supporting vertical storage solutions with ease

Advantages

- Lifts goods to higher levels safely and efficiently

- Compact design ideal for narrow aisles and small spaces

- Reduces manual lifting and improves workplace safety

- Available in manual, semi-electric, or electric models

- Strong build for stable and reliable performance

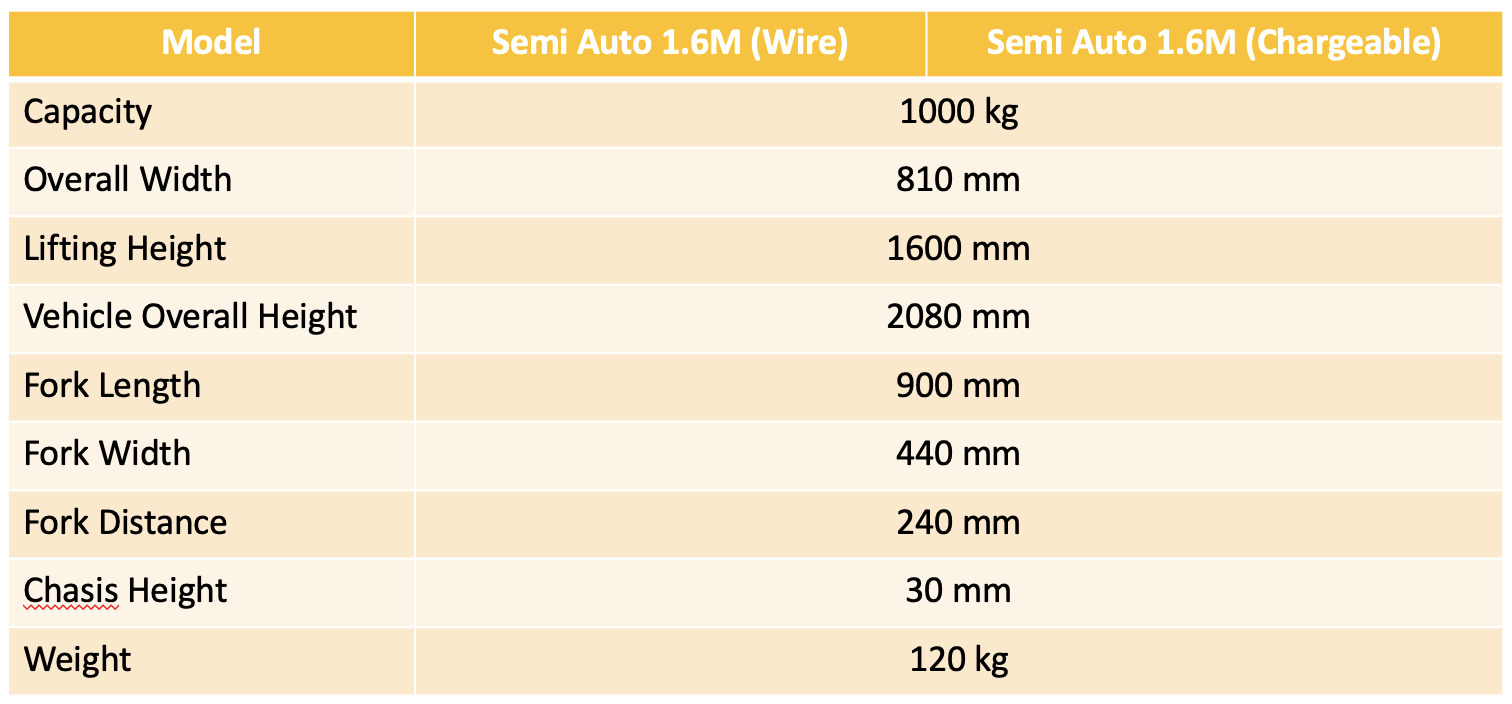

Manual / Semi-Electric Stacker

Stackers are designed to safely lift and move palletised goods to higher levels. Compact and easy to operate, they’re perfect for warehouses, stores, and tight workspaces.

Rotating Stacker (360°)

Rotating Stacker is designed with a 360° turnable body, making it easier to lift, rotate, and place pallets with greater flexibility. Perfect for tight working spaces and tasks that require precise positioning.

5 Easy Steps

1. Enquiry

Your journey begins with a simple enquiry. Once we receive your request, our team will review the details and match you with the right expert. We’ll then arrange a quick call or email to learn more about your goals and expectations.

2. Free Consultation

After your initial consultation, we’ll arrange a site visit to assess your space and needs in detail. You’ll meet your dedicated project manager, who will guide the process from start to finish—ensuring everything runs smoothly and efficiently.

3. 3D CAD Design

After the site survey, your project manager will recommend layout options tailored to your space and needs. We’ll then create accurate 3D CAD designs to help you visualise exactly how your facility will look once complete.

4. Instant Quote

You’ll receive a free, personalised quote with a full breakdown of the recommended equipment. We offer high-quality products at competitive prices, with reliable delivery times to keep your project on schedule.

5. Installation

We’ll agree on an installation schedule that suits your operations. Our accredited team will complete the setup, conduct a final inspection with you, and provide follow-up support, including annual safety checks.

Ready to make a change?

We are here to help you choose the best racking for your business. Schedule a call with our representative today.

FAQ

What industries benefit the most from using Stackers?

Stackers are widely used in warehouses, manufacturing plants, retail distribution centers, and logistics hubs anywhere that requires lifting, moving, or stacking pallets in tight or medium-sized spaces.

Why should I use a Stacker instead of a forklift?

Stackers are more compact and cost-effective than forklifts. They’re ideal for lower to medium lift heights and lighter loads, making them perfect for businesses that don’t need the higher capacity or speed of a forklift. They’re also easier to operate with minimal training.

How do Stackers help improve warehouse efficiency?

Stackers reduce manual lifting, allowing workers to quickly raise pallets to higher racks or move them across the floor. This improves productivity and helps optimize vertical storage, making better use of available space.

Are Stackers suitable for narrow aisles or small warehouses?

Yes. With their compact size and tight turning radius, stackers are excellent for narrow aisles and areas where forklifts are too large or cannot maneuver easily.

How do Stackers help reduce workplace injuries?

By lifting heavy loads mechanically, stackers greatly reduce the need for manual lifting, lowering the risk of back injuries and other musculoskeletal problems. This supports a safer working environment.

What should I consider when choosing a Stacker?

- Load capacity (how much weight it can lift)

- Lifting height (how high it needs to raise pallets)

- Type of goods or pallets handled

- Frequency of use

- Space constraints in your warehouse

How durable are Stackers compared to forklifts?

Stackers are built with robust steel frames and quality hydraulic systems to handle demanding daily use. While they generally handle lighter loads than forklifts, they are still highly durable and require less maintenance.

Can Stackers handle non-standard pallets or custom-sized goods?

Yes, many stackers have adjustable forks or special attachments that can accommodate different pallet sizes or unique loads.

Do Stackers require special training or certification to operate?

Most manual or semi-electric stackers only require basic operational training. However, for fully electric stackers or where local regulations apply, certification may be recommended to ensure safe handling.